Koppl Pipeline Services understands that in most cases, it is undesirable to stop the flow in the line or drain it completely in order to install a new valve. When a new valve needs to be installed, a valve insertion by a Koppl Pipeline technician is a quick and simple solution. Using new technologies and equipment, a valve insertion is also a very cost effective solution for many applications.

Valve Insertions Provide:

- The Need for Only One Excavation

- Quick Installation

- Immediate Results

- Water System Control

Valve Insertions Can Eliminate

- System Shutdown

- Draining of Water

- Chlorination

- Multiple Excavations

- Disruption of Service to Customers

Advantages to Performing A Valve Insertion:

- Flow remains ONLINE & UNDER PRESSURE

- Only 1 cut to the pipe

- Reduced project expense

- Reduced installation time

Use Fittings On Most Common Types of Pipe

- Cast Iron

- Pit Cast

- Ductile Iron

- Plastic

- Asbestos-Cement

Koppl Pipeline Services provides the valves from the manufacturers below:

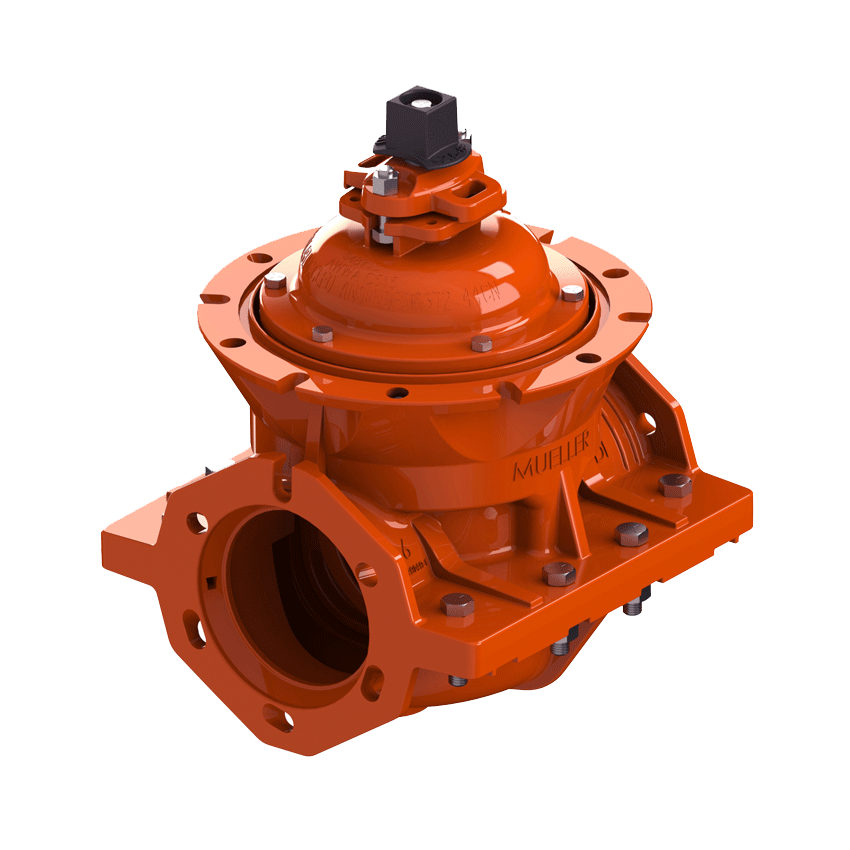

- Mueller® PermaSeal™ Insertion Valve

- HydraStop® Insta–Valve®

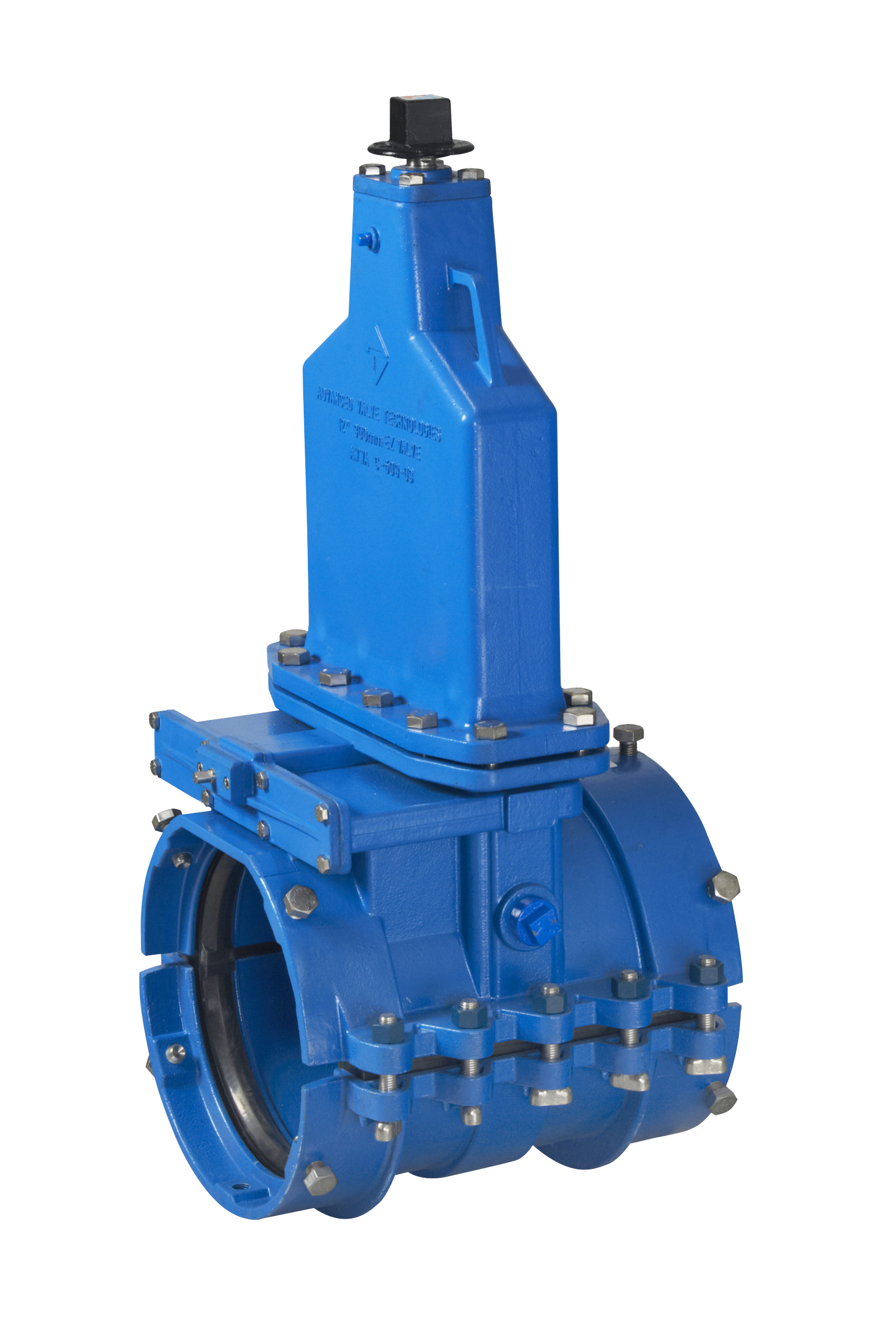

- Advanced Valve Technologies® EZ Valve®

- TEAM InsertValve™

Each system provides their own unique advantages. Give us a call today to see what process can offer the best solution to your need.

Valve Insertions are now available for pipe sizes 4” to 24” with some limitations. Please contact us for availability for your specific application.

Valves

Contact

Contact your local Koppl Pipeline Services representative.

Give us a call today to see what process can offer the best solution to your need.

- (323) 888-2211

- (323) 888-2232

Koppl Pipeline Services honors a legacy that has lasted for generations by bringing time-honored standards of quality and service to a modern age.

CCL#844802

AZCL#ROC216719

NVCL#0060642

HI#CT-31595